Many conveyor systems serve different purposes, from transporting bottles from a filling machine to an inline capper to a conveyor transporting massive mining products like coal into furnaces for energy production or conveyor belts moving boxes in an amazon warehouse expedite an order. There are also many different types of designs and principles of conveyor handling solutions for your material handling needs like:

- Powered drive conveyors: Electric motors power conveyors that mechanically turn a drive pulley with a particular design to match the type of conveyor belt you are using.

- Roller conveyors: Used commonly on boxes not powered, they have wheels on bearings, so when the product gets on top, it will freely roll with gravity rollers, and the following product coming behind will push the next creating a chain of transportation.

- Powered roller conveyors: Like a roller conveyor but includes some power rollers to move the products, often called motorized roller conveyors.

- Vibratory conveyors: These systems move parts and products by vibrating in a specific direction. Many food processing companies use it for sorting using meshing, mechanical separation, and sensors, among other uses.

- Screw Conveyors: Used for product handling of products in the space between the spirals; when the screw turns, it pushes the media, a great way to achieve vertical lift. This article will focus on the type of conveyors used in the bottling industry, the use, advantages, and cost analysis.

TYPES OF CONVEYORS USED IN THE BOTTLING INDUSTRIES

One of the main components of conveyor systems is the conveyor chain or belt conveyor. Based on the characteristics of the chain then, the conveyor frame, curves, and power drives are designed to match the correct specifications. The most popular designs in the bottling industries are:

Tabletop chain conveyor design

Tabletop conveyor belts are among the most widely used in automated conveyor systems globally; this type of handling equipment is used from small, semi-automatic liquid filling lines to multi-million Dollar machinery running thousands of bottles per minute. Within the tabletop family of belts, there are hundreds of options available, so to choose the best for your application, you would need to specify:

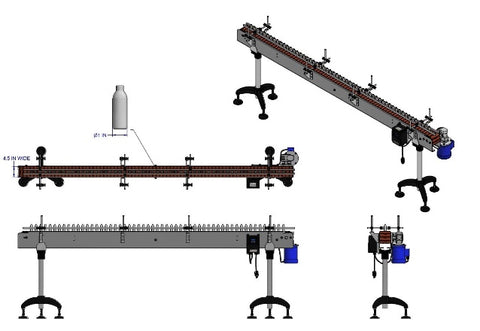

- Belt width: Different belt widths will be needed and make economic, engineering, or practical sense. The most common conveyor width in the bottling industry is the 4.5-inch tabletop, either straight or curved. A wide range of containers will work properly on a 4.5-inch standard design conveyor, including a 6-inch round gallon. The rails can be adjusted to accommodate it even if part of the base is not supported. Bellow, you can see cad models representation of the railing positioning.

-

1” CONTAINER ON CONVEYOR

6” CONTAINER ON CONVEYOR

- Belt length: The conveyor length needed for the bottle handling needs will play a significant role in the mechanical design of the conveyor system. A short conveyor (Less than 20 feet long) will work with basic designs and a small gear motor. Still, when conveyors get longer, and you add curves, you need to include self-tensioning features, bigger electric motors, and gear-boxes capable of handling the higher torque.

-

HANGING BELT TENSOR

- Conveyor transfers: Bottling and packaging production lines have several conveyors that need to transfer the containers from one to the other. There are many reasons to have more than one conveyor transporting containers in a bottling line. The main reasons are:

- The machines on these filling lines may have different handling speeds.

- A device in the bottling line starts and stops while others are continuous.

- A bottling machine will run better at different rates than others on the same production line.

The video below shows an efficient bottling line with transfers used to be able to run:

- The bottle unscrambler that feeds bottles into a continuous conveyor

- Transfers the containers to the inline filler where the conveyor stops each

- Transfers the bottles again to go into a bottle capper that requires continuous motion.

Choosing the correct method when transferring from one conveying system to another is essential, especially when handling unstable bottles or products. There are many options to move your containers from one conveyor to another. Bellow, please see illustrations of the most common ones with corresponding comments:

STRAIGHT TRANSFER

Curve turning capabilities or not: There are infinite shapes of belt systems, and each bottling project is different. And each conveyor manufacturer has its designs and preferences for each project. Some production lines are in a straight line. A linear line conveyor has the advantage of a lower cost and capabilities for future expansions. But some conveyors need to have particular shapes to fit into production rooms, go around other production lines, or be more efficient in the handling needs. For turning and curves, you will need flexible chain conveyors; you can find these in stainless steel conveyors, plastics, and other materials.

The temperature that it will be operating at: Certain parts of the conveyor handling line may require high-temperature capabilities; a typical example is when shrink sleeves are being applied into a bottle that then needs to go through a heat tunnel. Since most plastics that are often used in conveyors can’t handle the heat, a solution is to use stainless steel tabletop belt; in addition to the belts or chains, the bottom guides where the belt slides need to be of a low friction material that can withstand the friction and temperature, a good solution would be bronze guides.

The product that it will be in contact with to determine if it’s compatible with the belt material: Unfortunately, in the bottling industries, spills are common, so whatever tabletop belt material you are using needs to be able to withstand the products that will be running in your bottling line. This is a big concern primarily in chemical industries that bottle corrosive products; if the suitable material is not chosen, the belt may last a few days instead of a few years.